The leading provider of advanced robotic systems, Sarcos Technology and Robotics Corporation, announced today that it has completed final validation of its Project for autonomous manipulation of photovoltaic panels (O-AMPP) outdoors. During the field trial, Sarcos worked with leaders in the renewable energy industry including Mortenson, JLG Industries, Array Technologies and Pratt Miller to achieve this key milestone at a Mortenson project site validating Sarcos’ robotic solar array solution.

“Reaching this market validation and field testing milestone is a critical step in our journey to commercialize our robotic solar farming solution and ultimately improve safety and productivity in the solar farming industry,” said Kiva Allgood, President and CEO of Sarkos.

According to the Solar Energy Industries Association (SEIA), annual solar installations must increase by 60% by 2030 to meet the Biden administration’s goal for solar to reach 30% of US electricity generation by 2030. SEIA estimates that the industry needs to add nearly 900,000 new workers to reach this goal.

With the current labor shortage (US solar industry employed approximately 230,000 workers in 2020) and the high labor intensity of solar installation processes, the solar field construction market requires urgent and innovative solutions to ease the constraints to meet the increasing demand for solar energy. Robotic technology is expected to play a crucial role in overcoming the problems and accelerating solar deployment.

“We believe the O-AMPP system can address these challenges while improving safety, productivity and efficiency for our employees. It will also allow solar project developers to scale output and production to the levels needed to meet the Department of Energy’s renewable energy targets for 2030 and 2050. We are excited about the possibilities and potential impact of the O-AMPP systems in solar,” said Trent Mostaert, Mortenson’s vice president of industrialization.

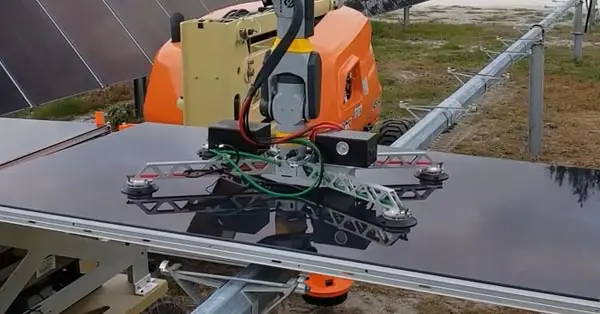

The O-AMPP project, which began in 2021 with funding from the US Department of Energy Solar Energy Technologies Office (SETO), aims to streamline the process of building solar arrays in a harmonized robotic system to deliver PV, detect , to lift and place modules in the area. Benefits for energy companies implementing the system for solar construction include lower project soft costs, the ability to participate in multiple projects at the same time, improved construction times and quality, and a safer job site that reduces the risk of injury, including lifting and fatigue. reduces injuries.

During validation of this system, a proof-of-concept O-AMPP system consisting of an Autonomous Working Vehicle (AWV) with the Guardian® XM robotic system and an Autonomous Delivery Vehicle (ADV) was used to monitor the flow of PV Optimize modules from delivery to installation.

Sarcos expects to launch its robotic solar field construction solution in 2024.